Changing Upkeep with the Transformer Oil Regeneration Process

Changing Upkeep with the Transformer Oil Regeneration Process

Blog Article

How Regenerated Transformer Oil Prolongs Transformer Life-span

The duty of transformer oil is important in guaranteeing the integrity and durability of transformers, offering as both an insulator and coolant. Restored transformer oil supplies an engaging option to enhance these features by properly getting rid of unsafe pollutants that endanger efficiency.

Importance of Transformer Oil

Transformer oil plays an important duty in the effective operation of electrical transformers. It mostly offers as a protecting medium, guaranteeing and stopping electrical discharges that elements operate securely under high voltage conditions. The oil's dielectric residential properties are basic to maintaining the honesty of the transformer, as they lessen the danger of failings that could result in disastrous cases or expensive downtimes.

Along with its shielding abilities, transformer oil likewise operates as a coolant. As transformers operate, they produce heat that has to be dissipated to stop getting too hot and subsequent damage. The oil distributes within the transformer, soaking up and moving warmth away from critical elements, therefore preserving ideal operating temperature levels.

Moreover, transformer oil works as a barrier against dampness and pollutants, which can jeopardize the performance and longevity of the transformer. Its chemical residential properties assist in reducing the effects of acids and other results that might develop with time, adding to the total health and wellness of the electrical system.

Advantages of Regenerated Oil

Furthermore, regenerated transformer oil has a reduced degree of impurities, consisting of fragments and impurities that can weaken performance. This purity not only enhances the oil's thermal conductivity but also extends the operational life-span of transformers by reducing overheating risks. The enhanced thermal security of regenerated oil makes sure regular efficiency also under high operating temperature levels, which is crucial for keeping transformer effectiveness.

Another advantage is its ecological influence. Regrowed oil advertises sustainability by minimizing waste and the demand for new oil manufacturing, thereby decreasing the carbon footprint linked with transformer maintenance. Regenerated Transformer Oil. Furthermore, the longevity of regrowed oil translates to lower maintenance prices gradually, as fewer oil adjustments and less constant tools downtime are needed.

Process of Oil Regrowth

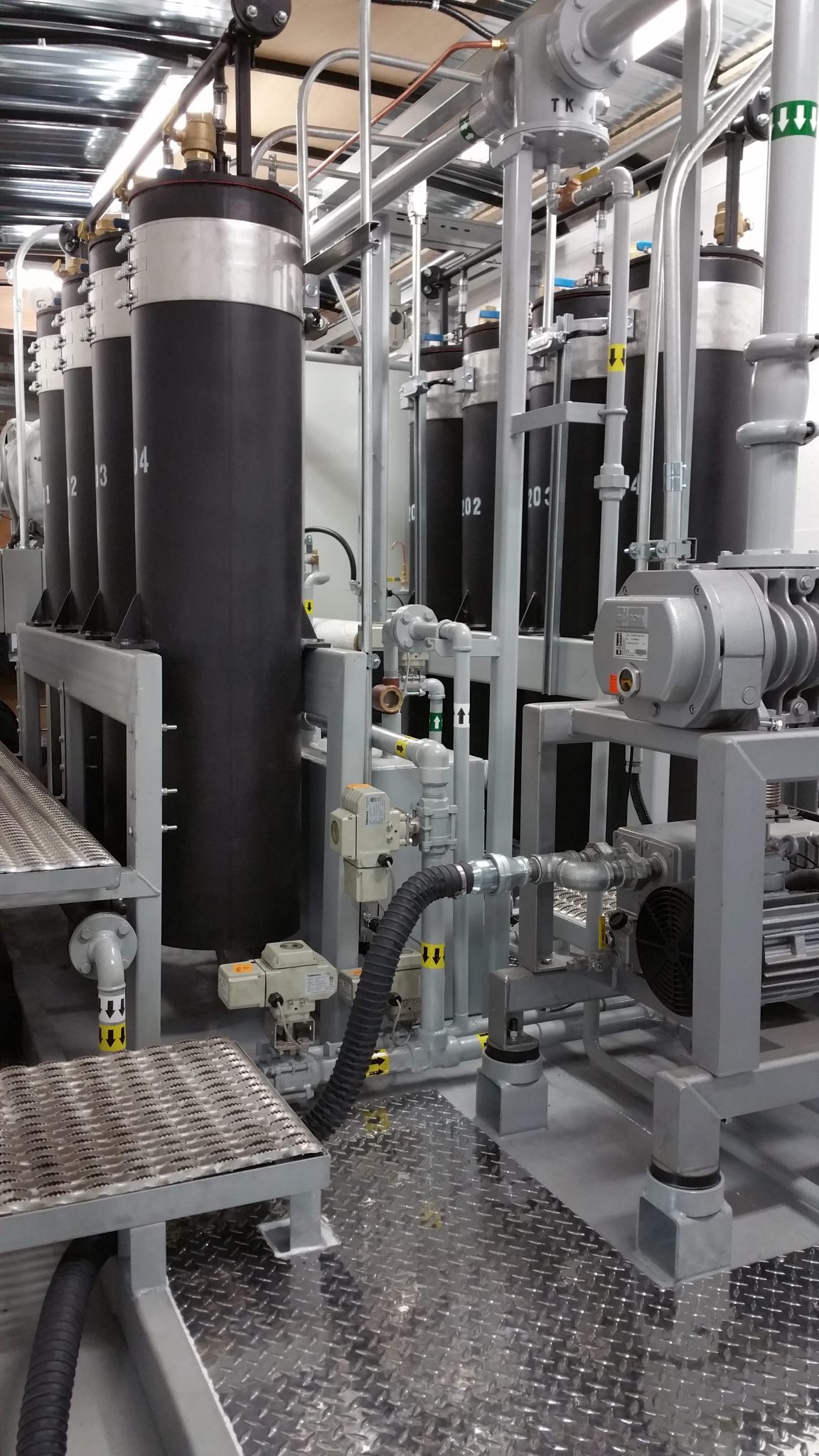

The regeneration of transformer oil entails an organized procedure created to recover the oil's initial residential or commercial properties and improve its efficiency. This process typically starts with the elimination of the used oil from the transformer, which is after that based on various purification strategies.

The initial step in the regrowth process is the filtration, where solid contaminants such as metal, sludge, and dirt particles are eliminated. This is often followed by vacuum distillation, which helps to get rid find out here of moisture and volatile compounds, consequently enhancing the oil's dielectric strength.

Effect On Transformer Performance

Bring back the properties of regenerated transformer oil dramatically affects the general efficiency of transformers. Boosted dielectric toughness is one of one of the most vital advantages, as it permits better insulation and lowers the likelihood of electric malfunction. This improvement results in a much more steady procedure under high voltage conditions, eventually resulting in boosted efficiency.

Additionally, the elimination of contaminants and destruction items throughout the regeneration process minimizes the risk of getting too hot. Cleaner oil assists in much better warm dissipation, which is vital for preserving ideal operating temperatures. As a repercussion, the thermal performance of the transformer is enhanced, permitting greater loads without compromising integrity.

In addition, the chemical security of regrowed oil ensures prolonged functional life. It resists oxidation and destruction, lowering the regularity of maintenance treatments and oil substitute. This security not just adds to enhanced performance but additionally straightens with sustainability goals by minimizing waste.

Future of Transformer Upkeep

As innovations in innovation remain to reshape the landscape of electric engineering, the future of transformer maintenance is positioned for substantial change. The combination of smart modern technologies, such as IoT sensors and predictive analytics, allows real-time surveillance of transformer health and wellness, boosting the capability to preemptively address problems prior to they intensify right into major failings. This aggressive technique not only optimizes Going Here functional effectiveness however likewise extends the life-span of transformers.

Additionally, the application of fabricated knowledge (AI) in information analysis permits more accurate fault detection and medical diagnosis. By leveraging device knowing formulas, maintenance teams can identify patterns in operational data that human analysts might forget, resulting in even more informed decision-making.

In addition, the adoption of eco-friendly techniques, consisting of making use of regenerated transformer oil, is readied to redefine upkeep procedures. This sustainable strategy not just minimizes environmental impact yet additionally boosts the general health of the transformer.

Last but not least, the shift towards automation in upkeep procedures is expected to streamline procedures, decrease downtime, and reduced expenses. As these advancements remain to develop, the future of transformer maintenance will unquestionably end up being a lot more effective, trustworthy, and lasting, ensuring the honesty of crucial electrical facilities.

Verdict

The application of regenerated transformer oil dramatically boosts the operational long life of transformers. By effectively restoring dielectric strength and thermal stability, this oil plays an important role in mitigating risks related check here to getting too hot and oxidation. The regeneration process not only removes harmful impurities yet additionally minimizes maintenance regularity and oil substitute expenses. Eventually, the adoption of regenerated oil stands for an essential improvement in transformer upkeep, making certain optimum performance and sustainability in the management of electrical facilities.

The duty of transformer oil is important in making sure the integrity and long life of transformers, offering as both an insulator and coolant.Transformer oil plays an essential duty in the effective operation of electrical transformers. Restored oil advertises sustainability by decreasing waste and the requirement for brand-new oil manufacturing, consequently reducing the carbon footprint connected with transformer maintenance.Recovering the buildings of regenerated transformer oil significantly affects the total efficiency of transformers.The utilization of regenerated transformer oil dramatically enhances the functional durability of transformers.

Report this page